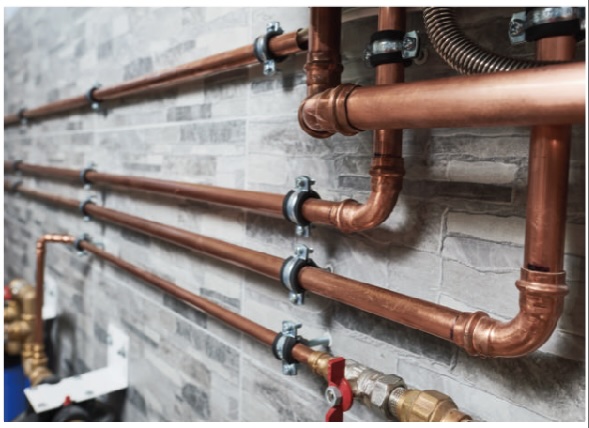

The use of press fittings and the most popular profile M is increasing exponentially. The M-Profile fitting is becoming the profile of choice for engineers including, M&E contractors and heating engineers alike.This is due to the wide range of different types of fittings that are available. It may not be common knowledge but there are specific M-profile press fittings suitable for potable water, open and closed circuits. These circuits would include heating and hot water and cold mains water. In all cases it is recommended to use a press fitting that is certified and tested thoroughly to make sure it is not substandard. The standard for potable water in the UK is WRAS and if certified all fittings would have a specific WRAS number. With the unique way that press fittings work is that it is a single press and closure of a joint without using any flames, solder or flux. This is ideal where there is a requirement for no hot work or in a tight space that would be dangerous to use a flame.

No hot work!

This type of connection requires a press tool, for instance a Z-Press from Zupper (www.zpress.co.uk) with M-Profile jaws. The mechanical joint is successful many times

over without the need for return visits or errors with soldering. Press fittings also are much thicker walled than conventional end feed and soldering fittings. This would explain why they are more expensive as they contain more material and are better manufactured. This reflects in their longevity and fit, as a user is less likely to experience a loose or misshaped fitting. It is also not being deformed or changed through heating and the addition of toxic and harmful, corrosive substances like flux. Flux also plays a role in creating pin holes in radiators and solder can easily block pumps and heat exchangers.

With press fittings being more stable, better made and actually not introducing contaminants into a system this also makes it ideal for the use on pipework that is used for gas. Natural gas that is used in heating and hot water boilers and other combusting equipment is often fed by a gas pipe that has to be made of metal. Unlike other pipe systems in a central heating, hot water or potable water system the transportation of gas to an appliance has a requirement to be in metal, either copper or steel. With these restrictions in place for safety the use of a press gas fitting is even more beneficial. This is because there is a single closure of the connection mechanically which reduces the opportunity for error and it does not introduce any new substances into the pipework. The correct press fittings to be used on gas are Cupro-Fit M-Press Gas fittings. These are different to the standard M-profile gas fitting and have no requirement to meet WRAS certifications and contain a different o-ring. The O-ring is the material that all press fittings us to make the connection once the fitting profile is pressed. This o-ring is a different material and tested to a different standard when in use for gas. The specification for an O-ring is HNBR and the fitting would meet requirements to BSI KME and approved to EN1245-7. These fittings in turn would have to be used on EN1057 copper tube. The o-ring is highly important to the connection and is denoted by the use of a yellow colour signifying gas. The normal M-Profile press fitting would use a black o-ring.

This is imperative to use a yellow gas press fitting on pipework that is transporting gas to any appliance. The fitting from Cupro-Fit clearly denotes it is for use with gas and if the user is unsure then the MPN (manufacturers part number) should be consulted.