Is there too much plastic in the built environment?

In a recent article by the Copper Sustainability Partnership and in conversation with Paul Hagar from Safe Piping Matters it suggests that there is a huge number of risks associated with the vast amount of plastic pipe within the built environment and being specified for use (https://www.installeronline.co.uk/do-we-need-to-reduce-plastic-pipes-in-the-built-environment). The industry is under scrutiny because of the amount it contributes to the GHG emissions as identified by the UN (38%) and with plastic in construction accounting for the second largest user and nearly 2 million tonnes of waste per year the opportunity to reduce this is immense. There has been great pressure on plastic waste within the supply chain for consume goods but little within the building sector. Just as in the domestic environment waste plastic can enter the food chain and the water systems to create disastrous consequences for the environment.

Where does plastic pollution start?

The biggest pollution issue is at the start of its life, when it is being produced and the emissions it creates. It is also from fossil fuels and although it has revolutionised materials and is extremely versatile in its applications there is a real issue with end of life and micro-plastic pollution negatively impacting on the water, air and soil. The end of life issue is generally tackled by burning with further creates harmful gases in the atmosphere.

Burning is also an issue when there is a fire within a property and Hagar suggests that a unit containing mostly plastic materials became fully engulfed within five minutes, whereas a property containing metal, wood and natural fibres lasted nearly thirty minutes. This was because the plastic burnt quickly and dripped within the voids between areas and the created toxic fumes that further exacerbated the fire.

How else does plastic pollution occur?

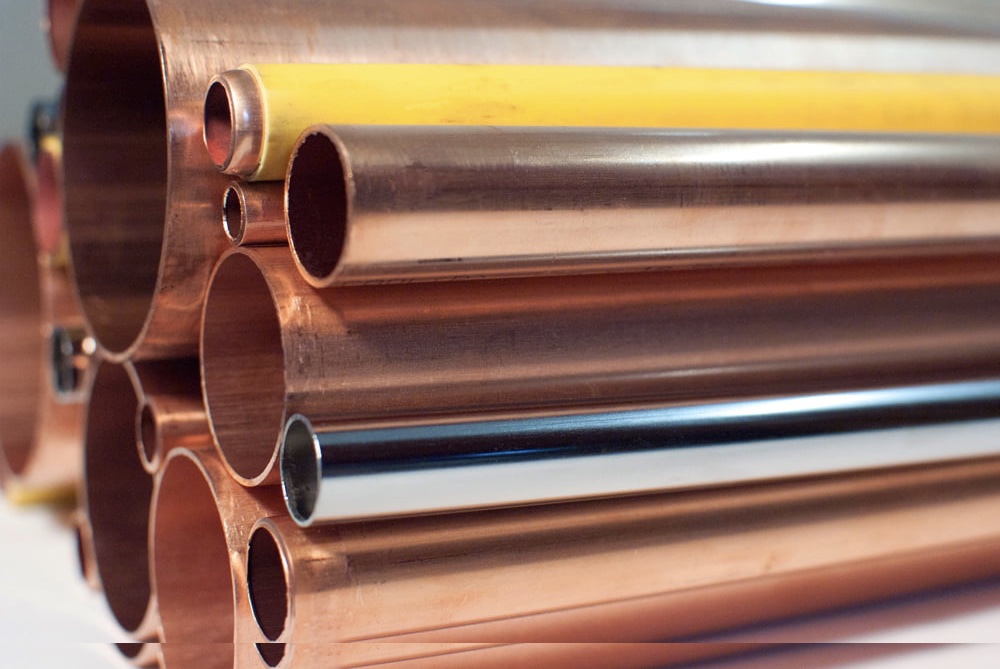

Plastic pipes also can leach out harmful chemicals when damaged or heated, by either exposure to the sun and elements or fire. Eventually plastic pipes will degrade far enough to leach into the water that it is carrying, this is why BPA free bottles and containers where designed and manufactured for water. Metal containers like stainless steel, steel and copper have been used for centuries to maintain the purity of water. Copper has been used to transport water through pipes and drinking containers throughout the world. These materials are also not flammable and do not leach out harmful chemicals into the water. The versatility and consistency of copper means it has been used in plumbing systems for heating, hot water and potable water by professionals that demand a material that does not leak or degrade. It is also fully recyclable many times over as it does not lose its properties. Also with the introduction of safer, cleaner and quicker plumbing systems like M-profile Press which do not use solder or flux the integrity and safeness of attaching fittings has greatly increased. Press fittings for example CUPRO-FIT, now offer a competitive alternative to solder fittings and do not require harmful heating of other

consumables to create positive connections. Flux and solder can build up in systems to negatively effect pumps and heat exchangers. The introduction of an extended range of fittings and valves means that a total press fitting system can be used to complete all jobs, like central heating installations, potable water systems and air conditioning applications.

The positive implications of using metal systems for water movement and storage are easily listed out and although there needs to be a more improved recycling rates and extraction process, copper can definitely be classed as a sustainable product that will solve some of the buildings industries requirements for the future.