Source DNV (2025)

As the world intensifies its push toward Net Zero, copper a critical material for electrification is facing a supply crunch. Demand for copper is expected to nearly double by 2035 due to the rapid expansion of clean energy, electric vehicles, and grid infrastructure. Yet primary copper production (via mining) is struggling to keep pace. At Cubralco Ltd, we recognise that closing this gap will require a strategic shift and copper scrap recycling is at the heart of the solution.

Why Copper Scrap Matters

Copper is infinitely recyclable without degradation in quality, making scrap a highly valuable secondary source. McKinsey & Company estimates that by 2035, up to 50% of global copper demand could be met by recycled material. Today, however, only 32% of copper used globally comes from scrap. This gap, what McKinsey calls the “lost copper” represents a massive opportunity for decarbonisation, resource efficiency, and economic growth.

The carbon footprint of producing copper from scrap is up to 80% lower than primary production. In a world focused on emissions reduction and circular economy practices, investing in scrap recovery, sorting, and refining infrastructure is no longer optional it’s essential.

What’s Holding Scrap Back?

Despite the clear benefits, copper scrap recycling faces several barriers:

- Poor collection and sorting systems in many parts of the world, especially in developing economies

- Complex product designs that make copper extraction from end-of-life products (like electronics or motors) difficult

- Export restrictions and informal scrap economies that reduce traceability and efficiency

- Lack of high-grade refining capacity to process low-purity scrap into high-quality copper products

These challenges result in significant copper being lost each year — either through landfilling, inefficient recycling, or being trapped in idle products.

A Call for Action: Improving Global Scrap Flows

To unlock the full potential of copper scrap, McKinsey suggests a multi-pronged strategy that Cubralco strongly supports:

1. Invest in advanced recycling technologies – Automation, AI-driven sorting, and metallurgical innovation can drastically improve scrap yields.

2. Establish global scrap supply chains – Improved logistics and material traceability are vital to ensure consistent quality and feedstock availability.

3. Encourage circular product design – Manufacturers must design copper-rich components with end-of-life disassembly and recovery in mind.

4. Support regulatory frameworks – Policies that support the legal trade of scrap and discourage landfilling are crucial to closing the loop.

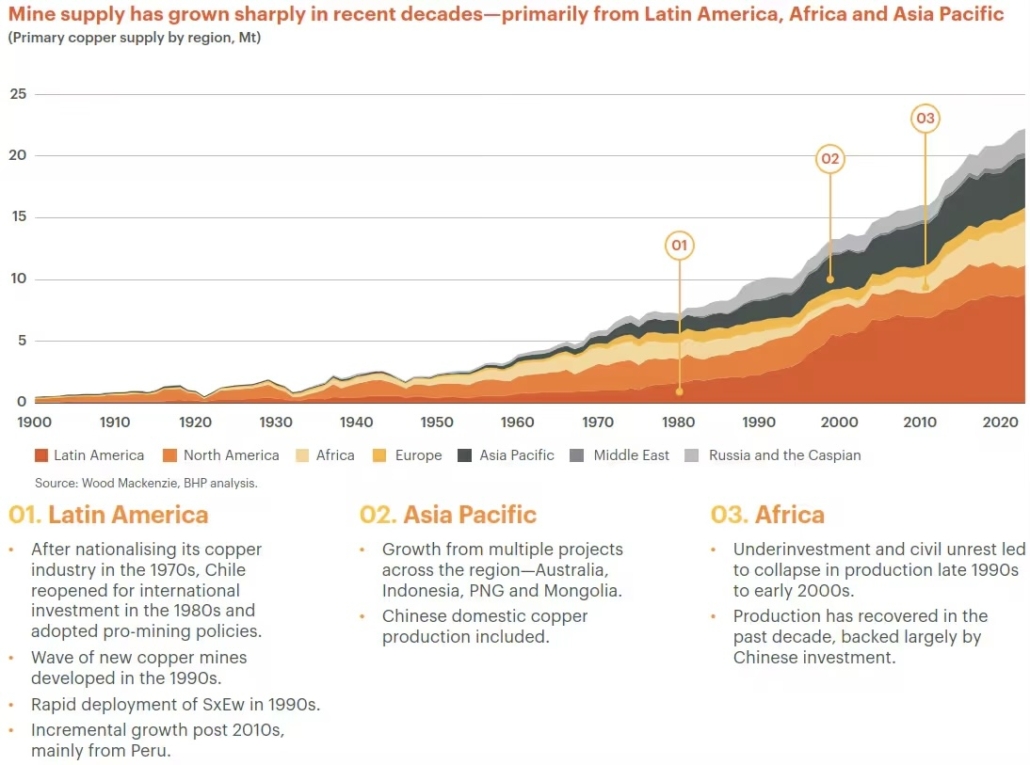

Source BHP (2025)

How Cubralco Supports the Circular Copper Economy

At Cubralco, we’re committed to advancing the circular economy in the UK and beyond. Our partnerships across the building materials and HVAC sectors increasingly focus on promoting press fittings and non-ferrous scrap recovery to extend the lifecycle of copper products.

We support:

- Merchant education on separating clean vs contaminated scrap

- Collaboration with recyclers to streamline copper flow from demolition and renovation projects

- Advisory on WRAS-approved press fitting systems that enhance disassembly and material traceability

Our goal is to align copper use in construction and manufacturing with broader sustainability objectives, helping customers decarbonise while preserving the value of vital raw materials.

Looking Ahead

Copper’s role in the energy transition is undisputed. As demand surges, embracing circularity through scrap recovery is not just good for business it’s critical for the planet. By scaling up recycling infrastructure, embracing smarter regulation, and designing for disassembly, we can unlock the lost copper that will fuel a low-carbon future.

To learn more about how Cubralco is supporting sustainable copper supply chains, visit our https://www.cubralco.com/sustainability/ page or contact us at https://www.cubralco.com/contact